More Website Templates @ TemplateMonster.com - March 10, 2014!

Activity Fields

3D/2D Numerical Modelization

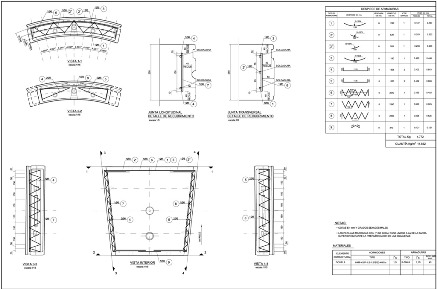

Segment Tunnels DesignSegment Tunnel Calculation

Fiber Reinforcement Concrete Segments

Face Pressure Calculation

Settlement Study

Conventional Tunnels

Underground Structures

Geotechnics

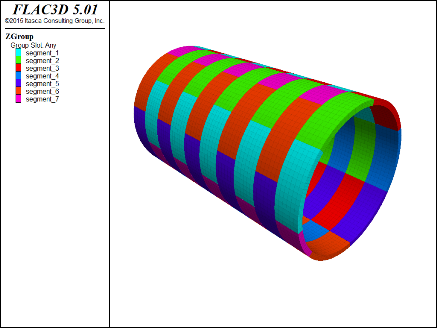

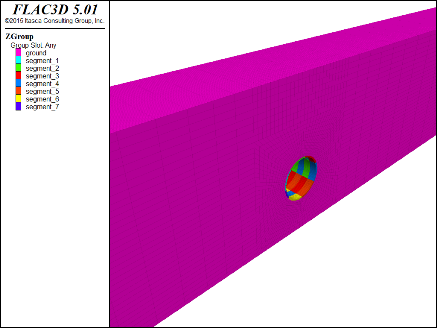

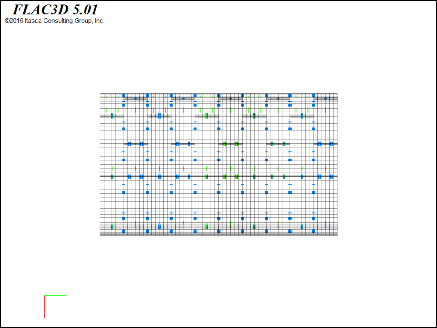

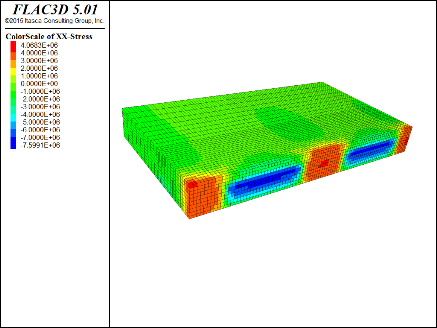

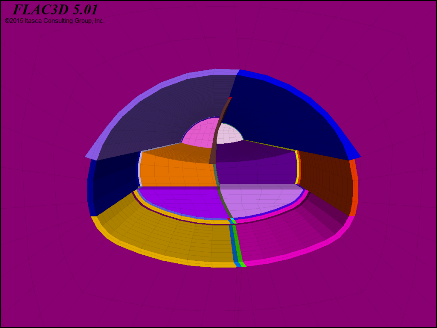

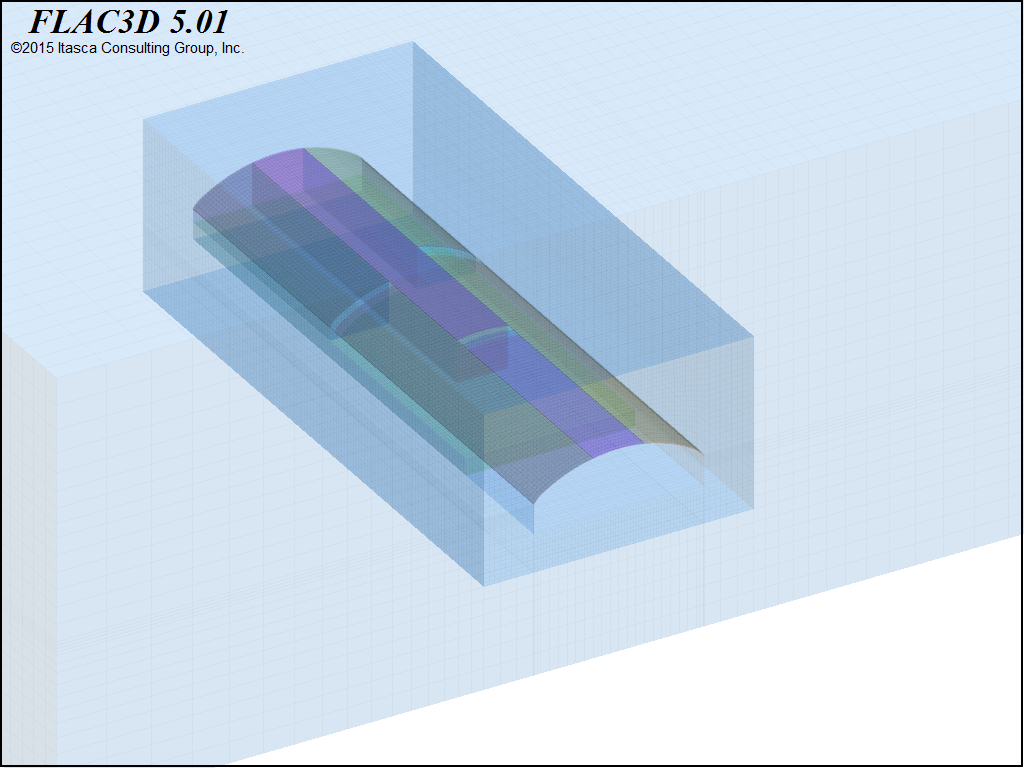

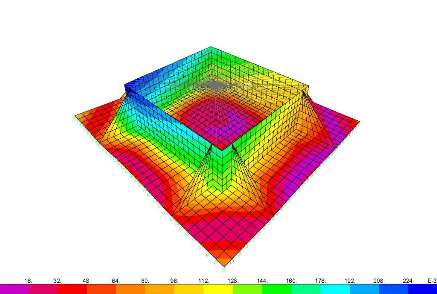

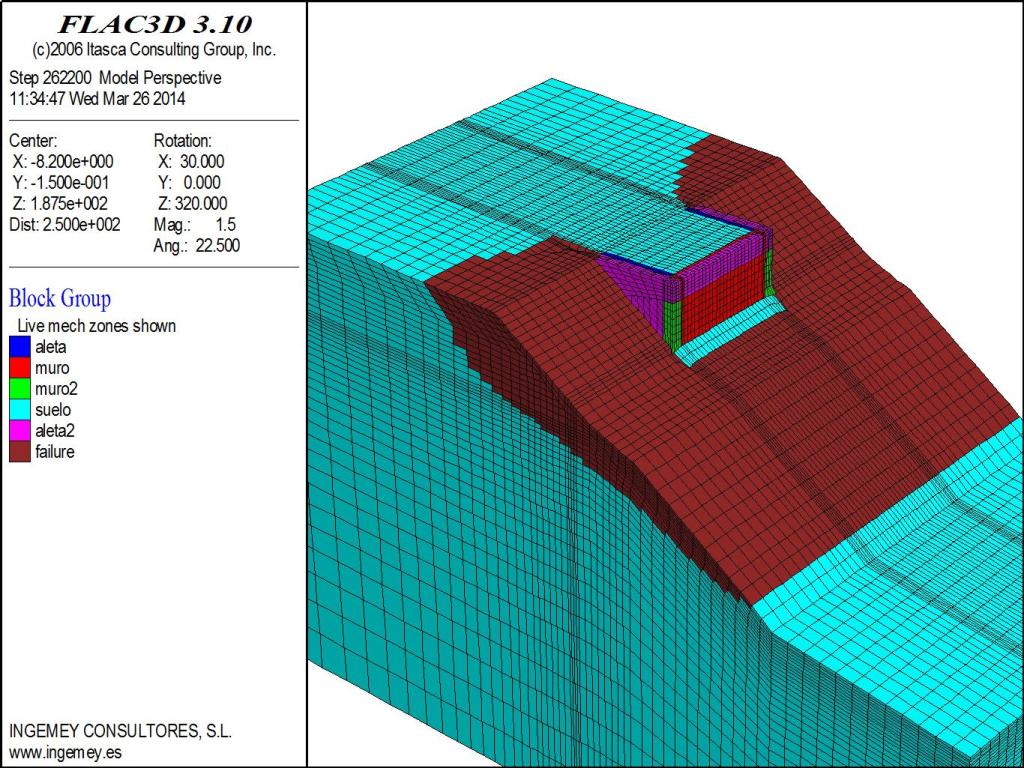

3D/2D Numerical Modelization

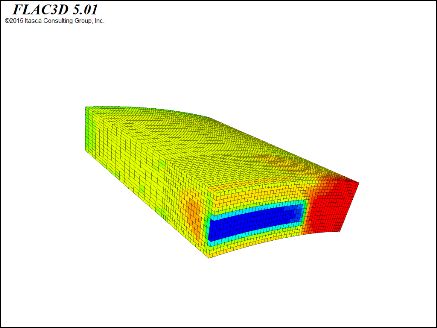

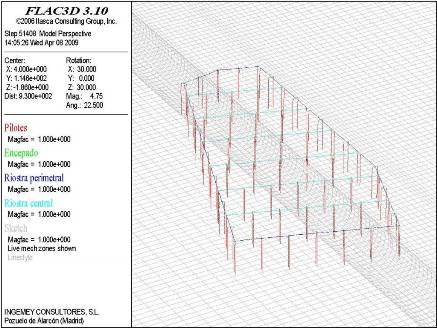

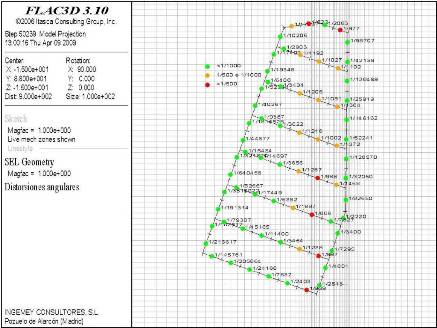

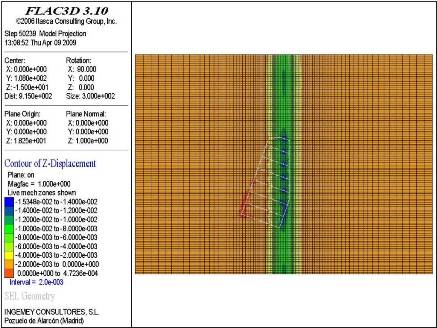

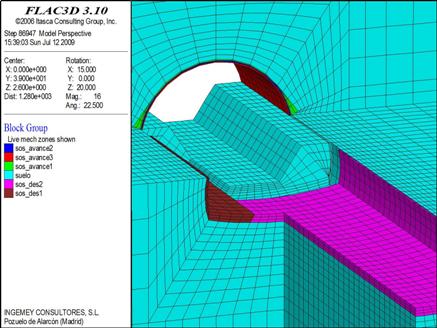

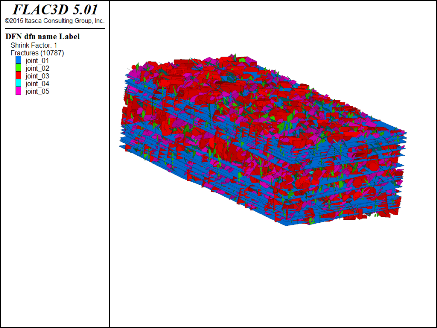

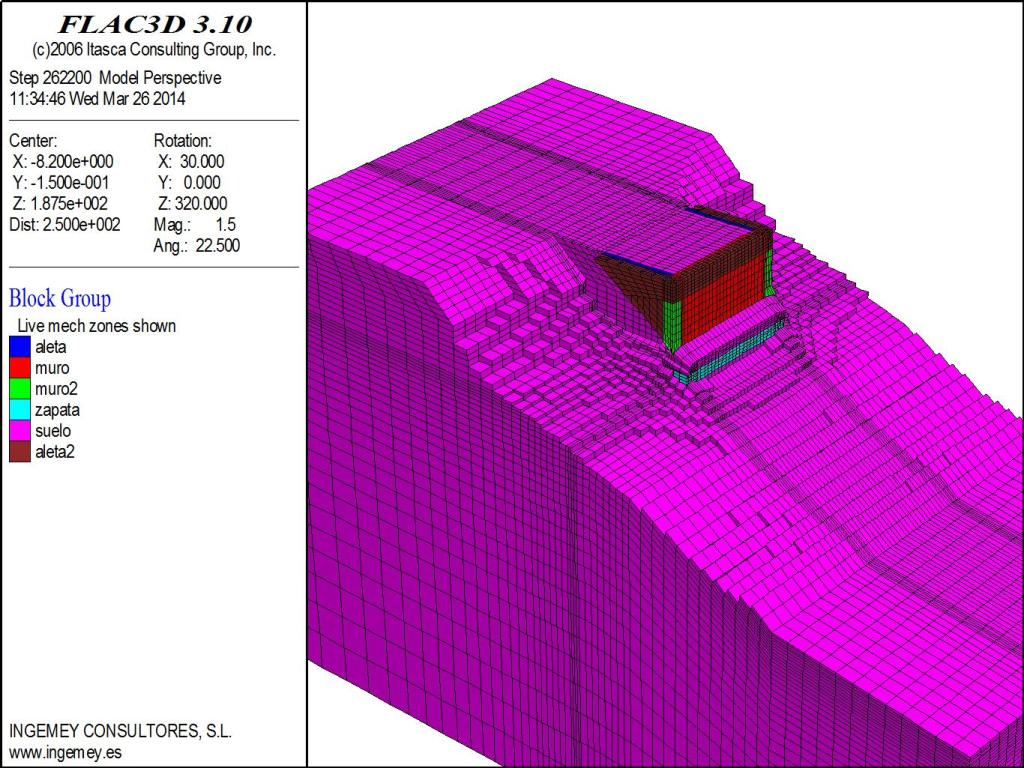

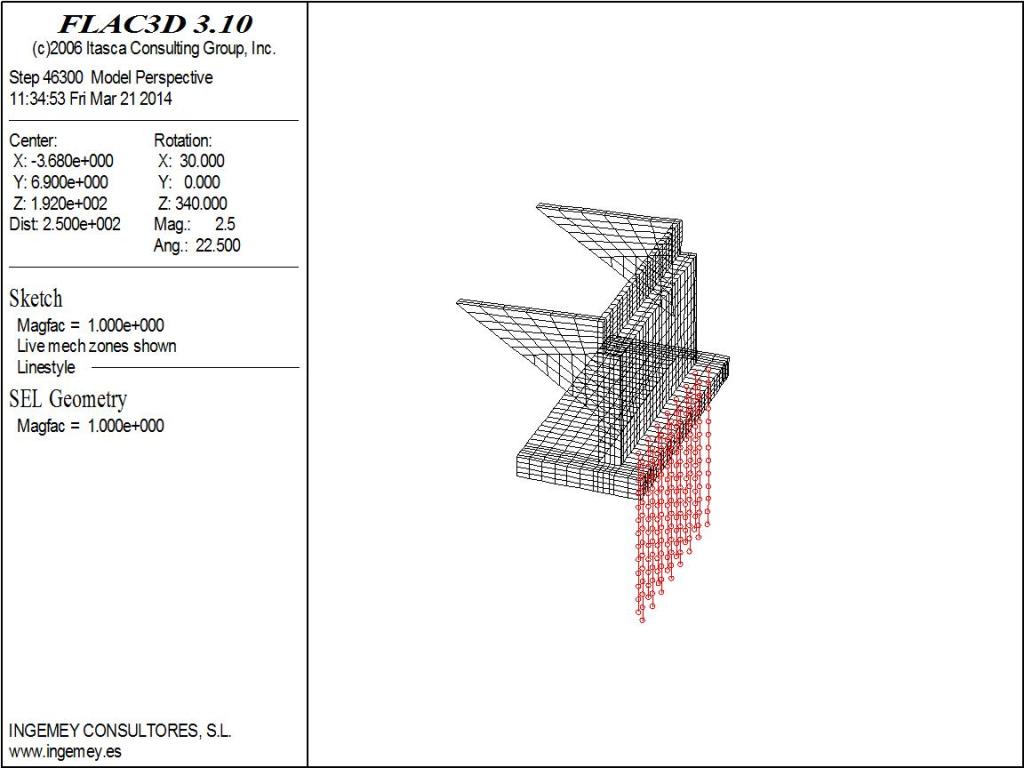

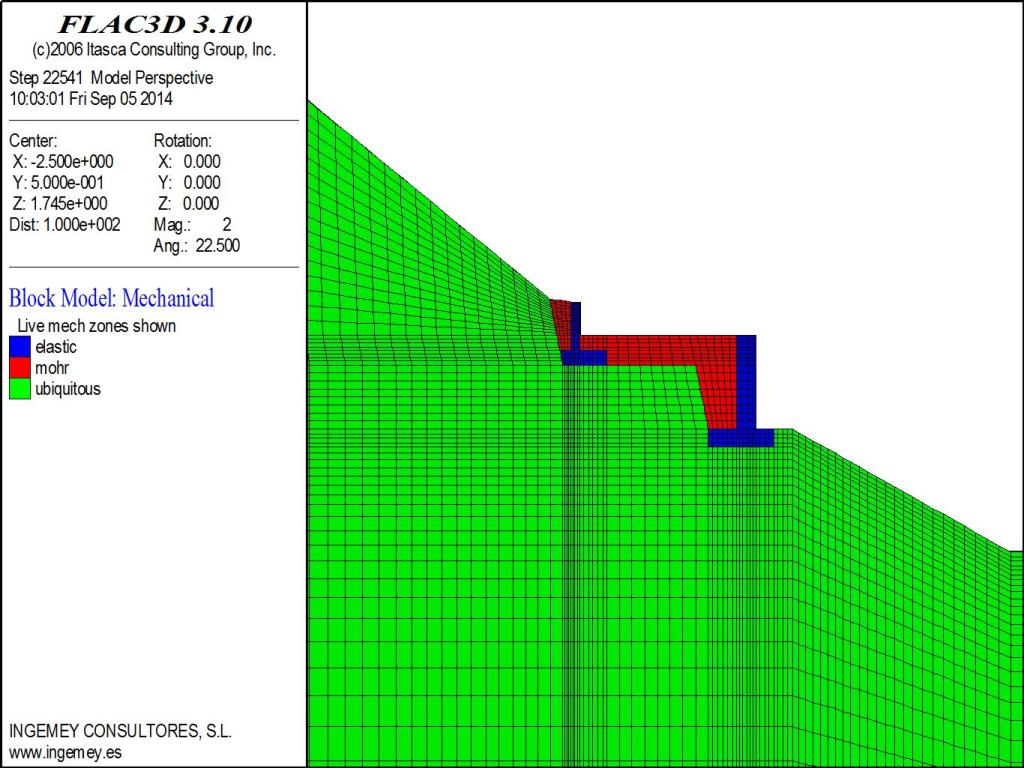

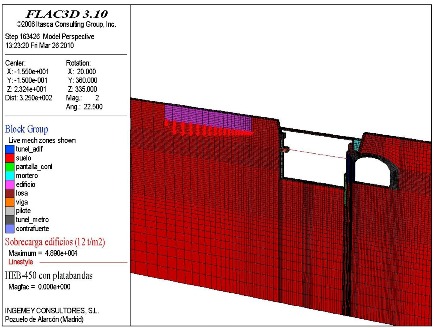

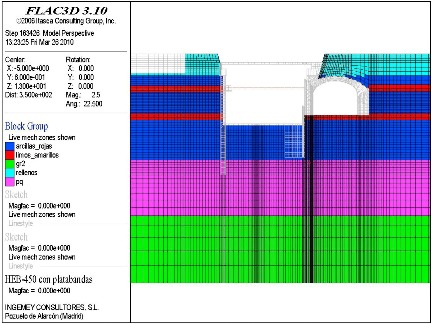

We have extensive experience in both geotechnical and structural numerical modeling of all kinds of complex problems in which soil-structure interaction is important. For this we have over 10 years experience in the use of finite difference program FLAC3D of Itasca Consulting Group among its characteristics may be include:- Ability to create complex three-dimensional geometries.

- Includes both materials with elastic behavior (Isotropic, Anisotropic and Orthotropic) as well as as elastastoplastic (Mohr-Coulomb, Hoek-Brown, Modified Hoek-Brown, Ubiquitous-Joint, Strain-Hardening-Softening, Bilinear Strain-Hardening / Softening Ubiquitous-Joint, Drucker-Prager, Double-Yield, Cap-Yield, Simplified Cysoil, Cam-Clay), which allows to simulate virtually any type of behavior.

- Allows entry of both linear structural elements (beam, cable, pile, liner) and surface (geogrid).

- It is possible to consider the flow and interaction with the ground (hydro-mechanical coupling), reproducing the consolidation mechanism

- Unlike other software programs, the model ca be set to work on large deformation, ie mesh geometry is modified from deformations. This feature is important, for example, in the case of excavation contour around the shield of an EPB.

As an example of some geotechnical problems whose complexity makes necessary to make a 3D study can include:

- EPB excavated tunnel

- Conventional Tunnel, in order to simulate the different phases, consider the effect of the distance to the front of excavation and avoid imposing a relaxation in the ground calculated with more or less arbitrary methods

- Stations.

- Interactions with existententes tunnel structures, buildings or other tunnels.

- Modelling of nonlinear elements (eg fibers reinforced concrete).

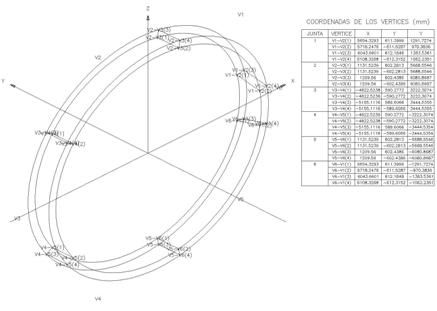

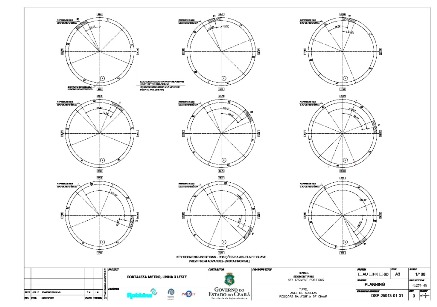

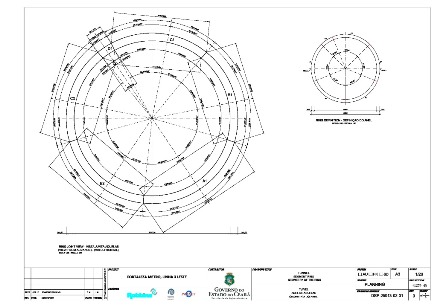

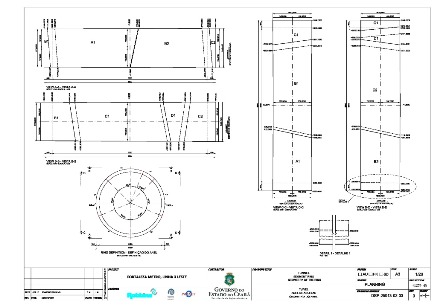

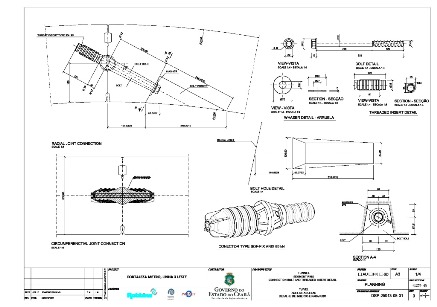

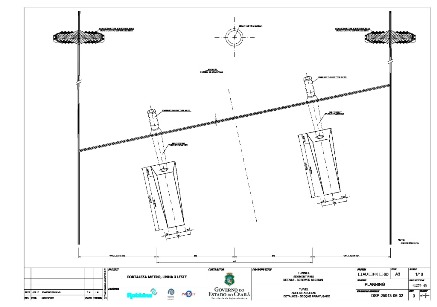

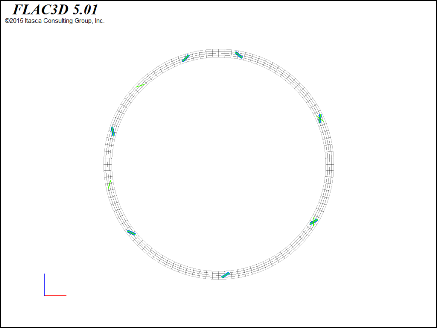

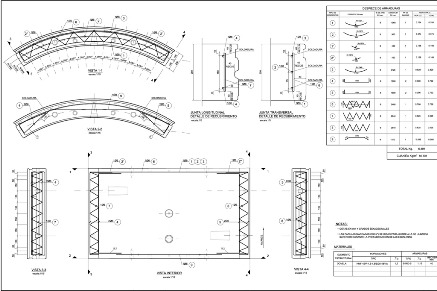

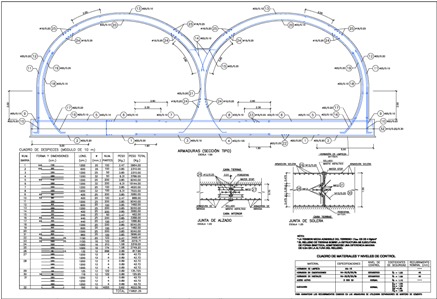

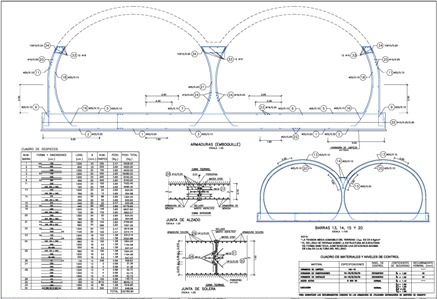

Segment Tunnels Design

As is known, the geometric design and the definition of the details at the joints has a great impact on the costs of implementation and installation times by influencing both the speed of advance and productivity of the work.INGEMEY has developed its own Software TSD (Tunnel Segment Designer) that allows the geometric definition of the keystone in a much faster and eliminates the possibility of human error in generating geometry. The program is very versatile, allowing virtually any configuration of the ring. Among the variables that can be defined are:

- Number of segments in the ring

- Ratio between key and regular segments.

- Number of thrust shoes/connector in each segment.

- Conicity.

- Angle measured in the development of the inner surface for each of the joints.

- Adicinal angle in the transverse plane for each of the joints.

- Joint geometry.

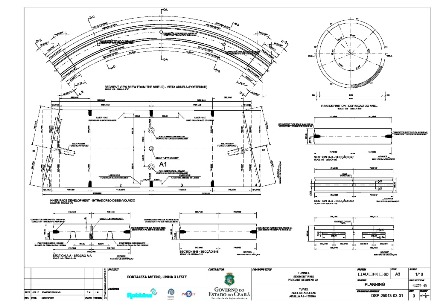

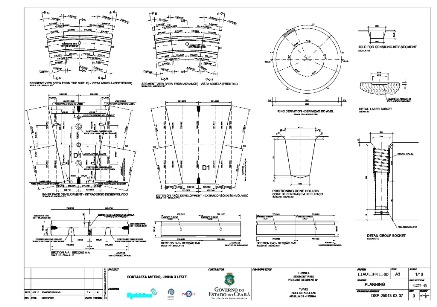

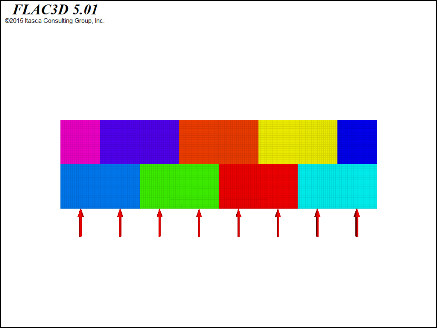

Segment Tunnel Calculation

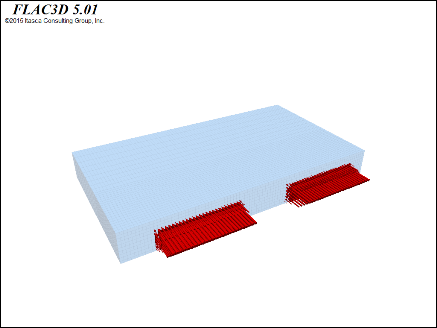

We have extensive experience in the calculation of segments. For this we have developed a calculation process having into account all loads acting on the segments, both once placed as during the previous phases. The following phases are studied- Temporary phases (demoulding, tumbling, storage, handling, assembly ...)

- Efforts at transversal joints (between rings) due to the thrust of shoes (Spalling and Bursting effects).

- Ground loads on the ring.

- Efforts at the longitudinal joints (between segments of the same ring) due to thickness reduction (Bursting effect).

- Verification of connectors between rings (Pull out and shear).

- Lip effect in transverse joints.

Our experience, backed by calculating a large number of tunnels segments, allows us to optimize the solution without compromising safety and durability, so that the thickness of slices to be "as thin as possible, as thick as necessary".

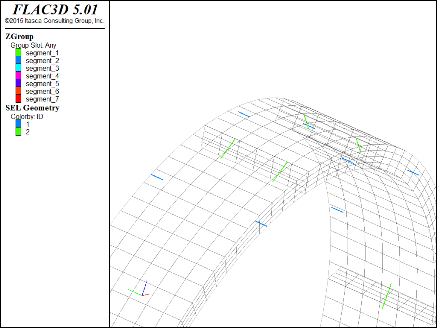

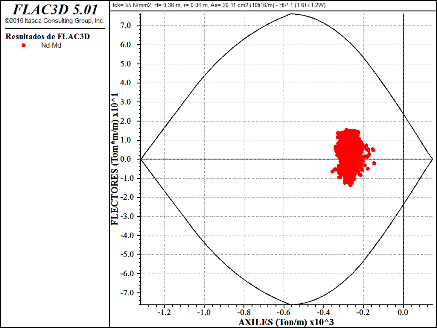

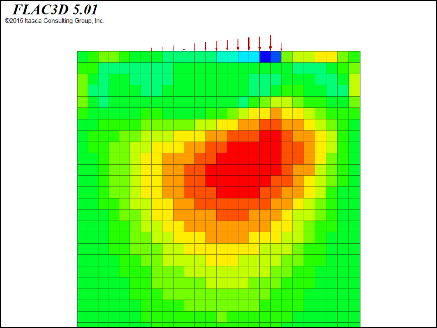

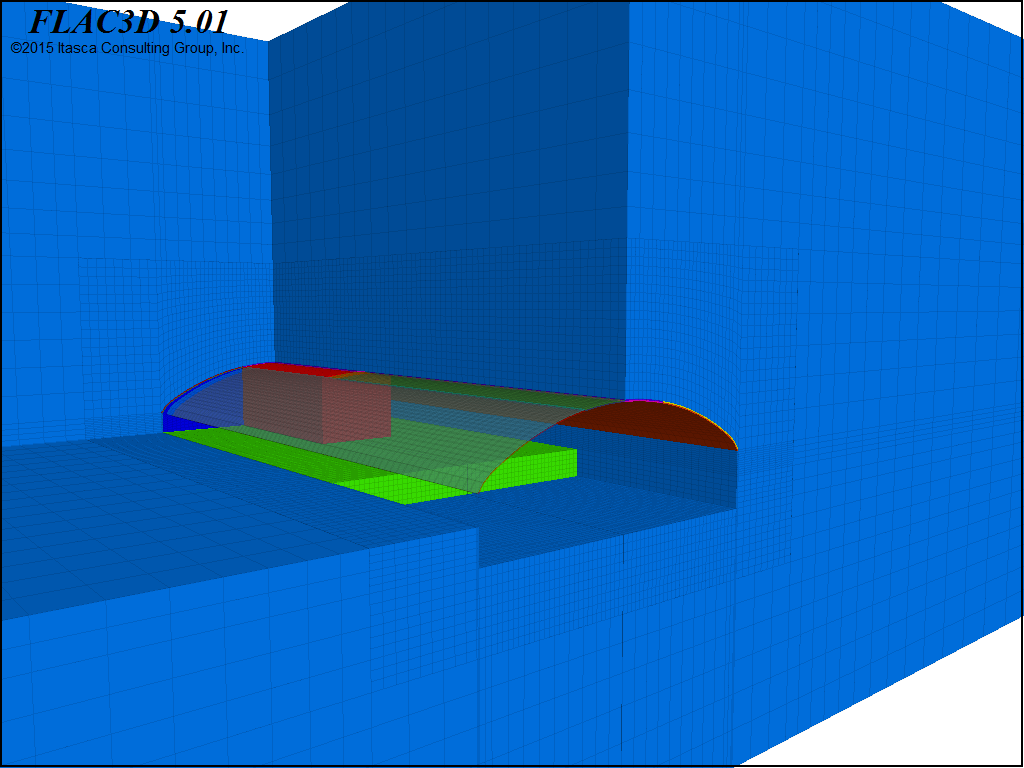

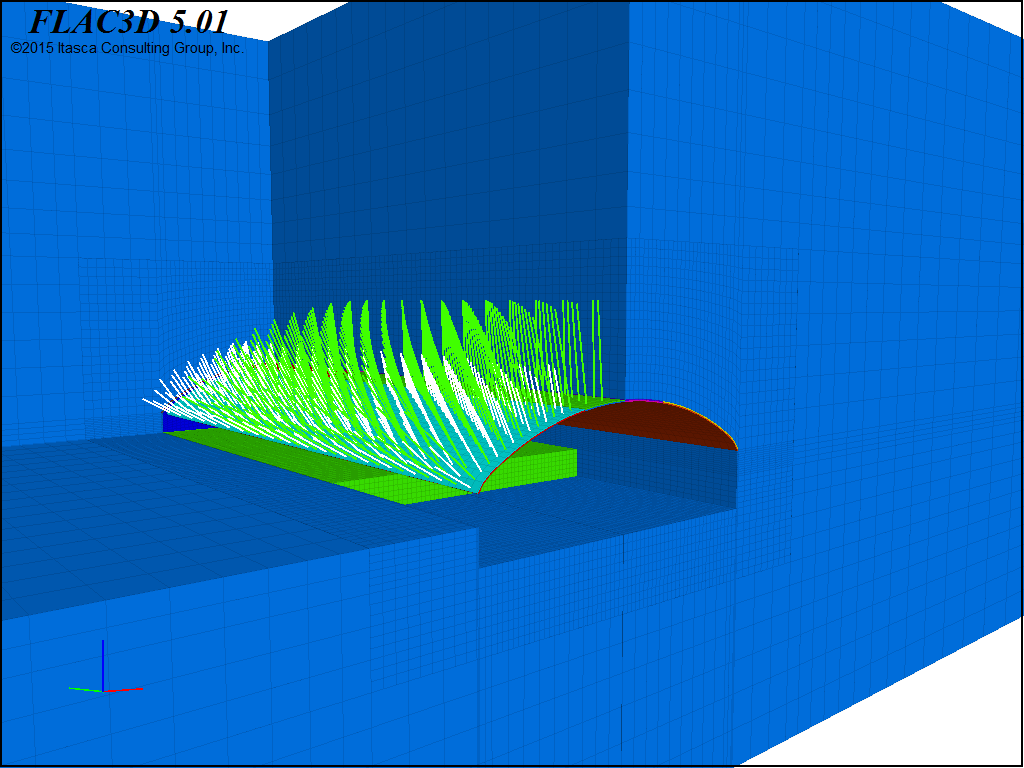

For calculating segments under ground loads complex three-dimensional models have been developed that include both the field and the segment. Such models allow the introduction of ring joints, both transversal and longitudinal, incorporating both connectors/bolts in transversal joints as the bolts between rings between segments of the same ring.

Regarding checking Bursting and Spalling effects on joints, three-dimensional numerical models are used, allowing to obtain results that are more suited to real respect to those obtained with classical methods (Leondhart for Bursting and Schleeh effect the Spalling). Among the advantages of numerical modeling include:

- Is possible to introduce the actual geometry of both the segment and contact shoe-segment.

- Is possible to introduce eccentric loads.

- In the same calculation is considered both Bursting and Spalling effects.

Fiber Reinforcement Concrete Segments

Fiber reinforced concrete (FRC)) has been used as reinforcement of concrete tunnel segments for over 25 years. The introduction of structural fibers, both steel and synthetic in concretes of high mechanical performance results in improved material behavior in various aspects of its functionality in tunnel structures. In particular, the use of fibers concrete reinforcement is well adapted to the case of segment tunnels , since in this case it is primarily compressed elements with relatively small bending efforts.Knowledge and development related to the structural use of HRF is large, there are numerous references and, above all, is covered by guidelines and national and international regulations. The use of structural fibers is already regulated at European level in several states: in Germany with the DBV 2001 in Italy with the CNR-DT 204 in Spain with EHE-08 and, in addition, there are regulations of European character set by RILEM committee and internationally 162 new Model Code of 2010. All these codes and design guidelines include fiber concrete as a structural material and pose estimation methods based on the theory of limit states and partial safety factors in the same line of design criteria established and accepted for reinforced concrete and / or traditional prestressing. Importantly, too, that the drafting committee of the EC-2 is also working to include in the new version the HRF as a structural material.

Briefly, the main advantages that the structural fibers introduced in concrete are:

- Toughening in the concrete surface, ensuring a greater capacity to withstand impact and prevent breakage of the coatings.

- Increased ductility in the concrete mass, due to the ability to distribute the fibers tridimensionally, reducing the fissures width. Also, with a sufficient amount and meeting regulatory requirements, synthetic fibers can secure for themselves the ductility of the concrete section, avoiding the risk of brittle fracture, equivalently to the minimum amounts of conventional reinforcement.

- Reducing plastic shrinkage of concrete during setting and hardening.

- Increased durability, not only by reducing associated wearing reinforce using fibers, but by the ability to reduce the initial cracking of concrete and water barrier and chemical resistance in the case of synthetic fibers.

- Synthetic fibers produce a favorable effect on the conditions of fire in a tunnel. While the structural fibers are not specific to treat pathologies that concrete undergoes during fires, the advantages over steel reinforcements are remarkable.

- Faster execution of the rebar and better conditions for operators during concreting operations, also resulted in a positive increase of the security.

- Allow reducing the amounts of steel used in reinforcing the segments, providing the armor where it is really needed for concentrated loads received during the different phases of the tunnel, and maintaining ductility with the use of fibers in the segment. Thus reinforce performed more rational, since they are proportional to the loads received and ensure the safety factors of the regulations.

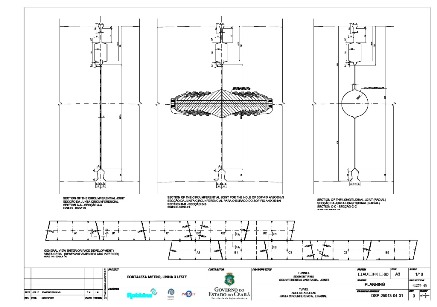

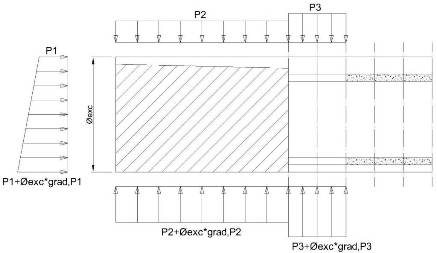

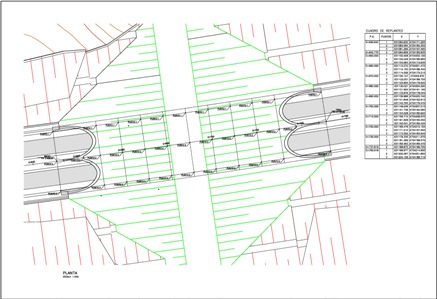

Face Pressure Calculation

It is well known that the handling of tunneling machines working with pressure on the front is complex. To counteract the external pressure (due to water and ground) by which it is exercised in the chamber, it is important to study the precise value of this pressure (as both an excess and defect it may have a destabilizing effect) in depending on the nature of the materials and their geotechnical properties and the position of the water table. With good pressure control is achieved limiting conditions on surface while a too high pressure greatly increases the tool wear, stopped progress and may, in turn, cause instabilities, also increasing the time of inspection and maintenance.The main objectives of the pressure at the front are:

- Hold the front.

- Minimize surface deformations.

Moreover, the holding pressure level depends on:

- Geotechnical soil propertie.

- Water table position.

- Excavation method.

- Covering.

- Dimensions of the tunnel.

To obtain working pressures a number of models which represent possible mechanisms for breakage at the front are studied, as well as to determine the properties of the holding means able to prevent the collapse, which combined with numerical sensitivity analysis and our extensive experience in the application of safety factors lead to the best solutions.

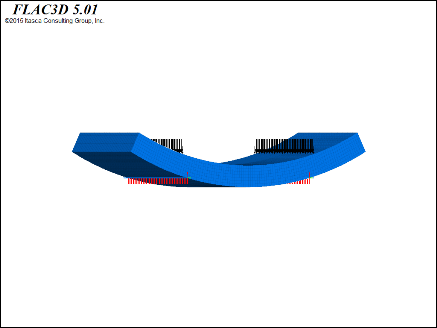

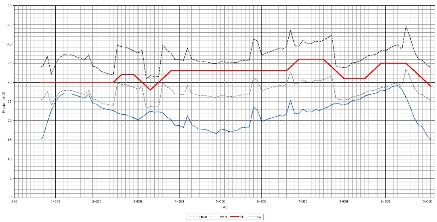

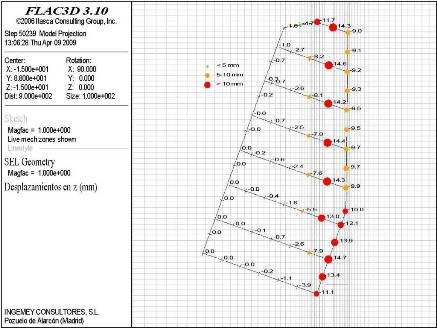

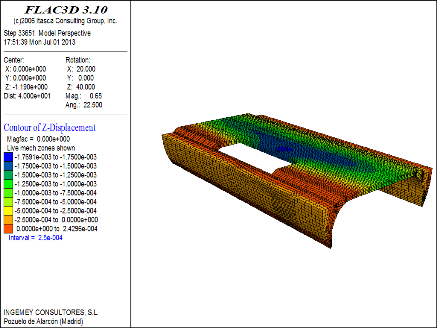

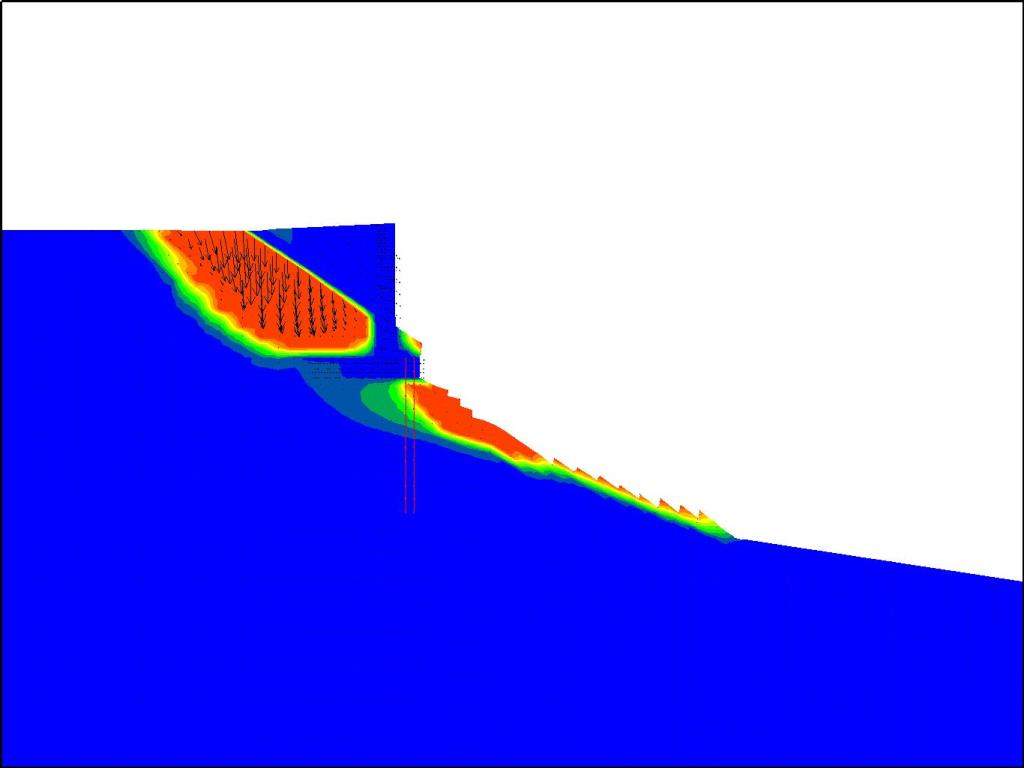

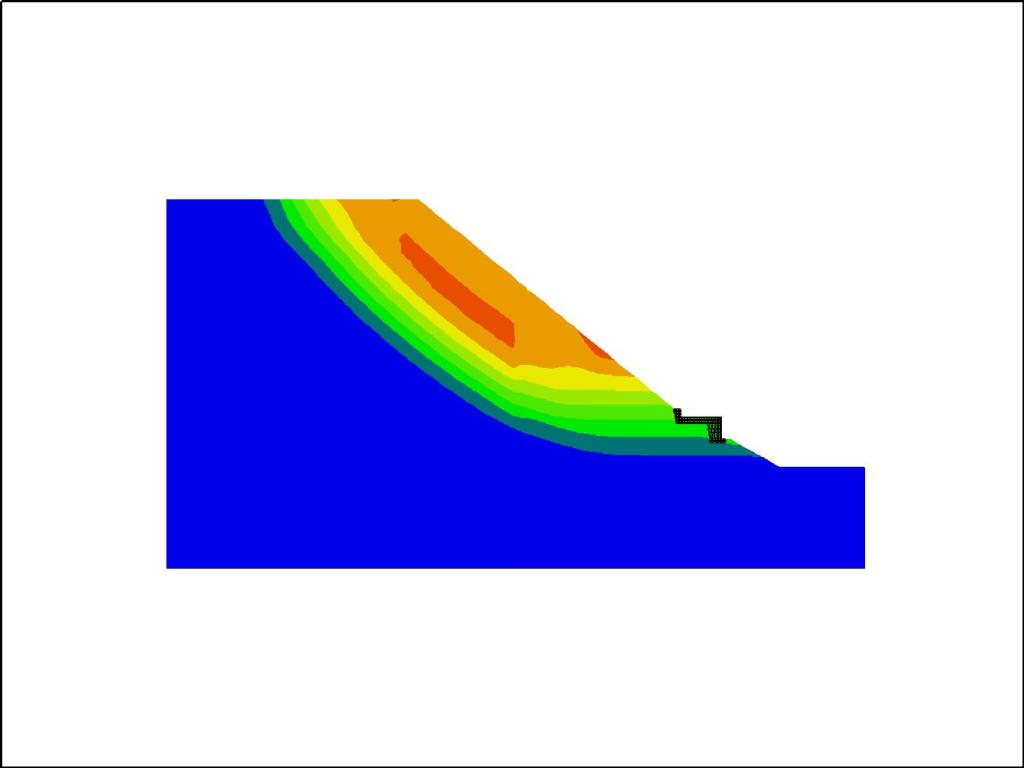

Settlement Study

As is well known, the requirements for tunnel projects in urban areas are increasing. Infrastructure and sensitive buildings must remain undamaged after excavations, which often required groundimprovement measures that increase very significantly the cost of the project.It is therefore critical adequate assessment of the movements that are likely to occur during the execution of the works, as well as the study of the possible effects on other structures or buildings.

In this sense, the biggest advantage of numerical modeling against other tools to estimate the seatlements produced by excavating a tunnel is allowed to consider into the scheme of calculating the actual construction process and can be included the structures on which we want to analyze the effects of the excavation.

Furthermore any additional treatments may be considered and optimized the calculation model, thereby achieving a more efficient and economical solution.

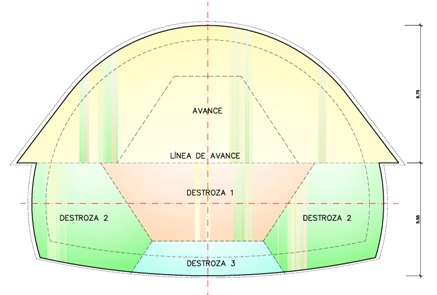

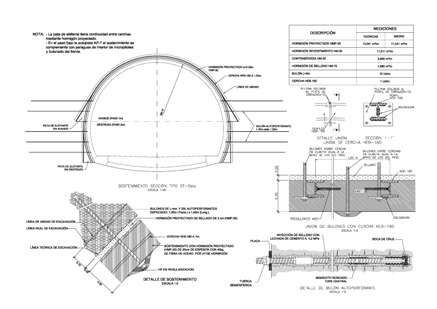

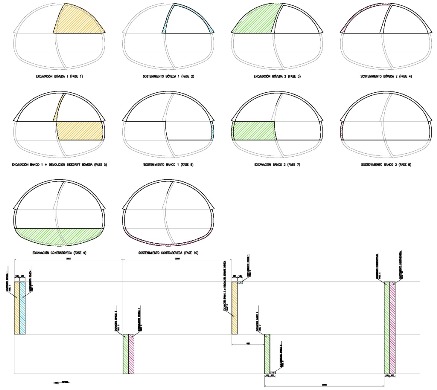

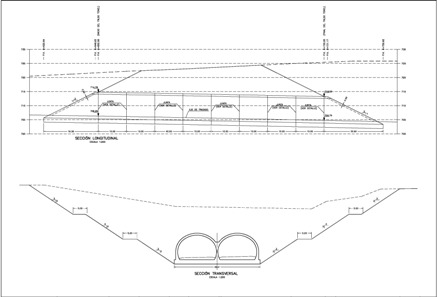

Conventional Tunnels

We have extensive experience in the design and calculation of tunnels excavated with conventional methods. While the current trend is tunneling by TBM, there is still a large number of tunnels that are excavated by conventional methods which, unlike excavated with TBM, provide a very flexible process that can easily make the following changes during the construction:- Increase or decrease the supports (both shotcrete and bolts).

- Vary the time / distance to the front of the different phases.

- Increase or decrease the length of excavation advance.

- Segmenting the excavation face depending on the geological characteristics.

- Perform ground treatment.

In INGEMEY we specialize in optimizing the solution from execution and economical point of view , both concerning the definition of the different phases (Setting the advance lengh, excavation face segmentation, ...) and regarding the support (shotcrete thickness optimization, number and length of bolts, ...). For this is useful three-dimensional numerical modeling, as it allows sensitivity analysis of various parameters (Advance, supports, stability of the front) and achieve the most efficient solution.

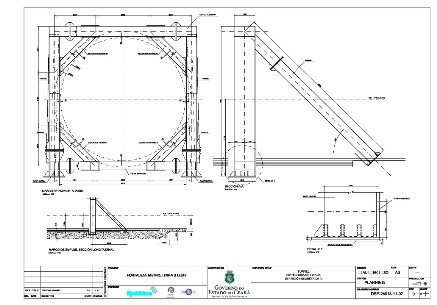

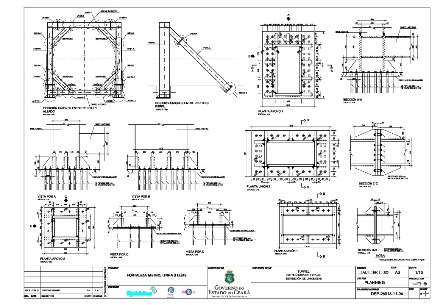

Underground Structures

According to our expertise work for companies have participated in the design and calculation of all types of structures. For this task we have the most advanced software, both commercial and internally developed.Among our private activities in the field of structures include:

- Stations.

- Slabs.

- Metalic structures.

- Thrust structures.

- Reinforced concrete walls.

- False tunnels.

Geotechnics

According to our expertise work for both construction and consulting companies in the various fields of geotechnics (High Speed Lines, Lines Metro, Roads, Ports, Pipelines, ...).Among our activities in the field of geotechnical include:

- Soil mechanics.

- Rocks mechanics.

- Slopes.

- Ground anchors design.

- Geotechnical Consultancy. - Earth structures (fills, dumps and spoil tips).

- Shallow and deep foundations.

- Excavability assesment.

- Hydrogeological studies.